过程工程学报 ›› 2021, Vol. 21 ›› Issue (7): 786-793.DOI: 10.12034/j.issn.1009-606X.220206CSTR: 32067.14.jproeng.220206

收稿日期:2020-06-28

修回日期:2020-08-21

出版日期:2021-07-28

发布日期:2021-07-27

通讯作者:

鲁进利 1280350428@qq.com;lujinli@sina.cn

作者简介:吴丽(1994-),女,安徽省安庆市人,硕士研究生,供热、供燃气、通风及空调工程专业,E-mail: 1280350428@qq.com基金资助:

Li WU1( ), Jie HE1, Jinli LU1(

), Jie HE1, Jinli LU1( ), Yafang HAN1, Ze HONG2

), Yafang HAN1, Ze HONG2

Received:2020-06-28

Revised:2020-08-21

Online:2021-07-28

Published:2021-07-27

Contact:

Jinli LU 1280350428@qq.com;lujinli@sina.cn

摘要:

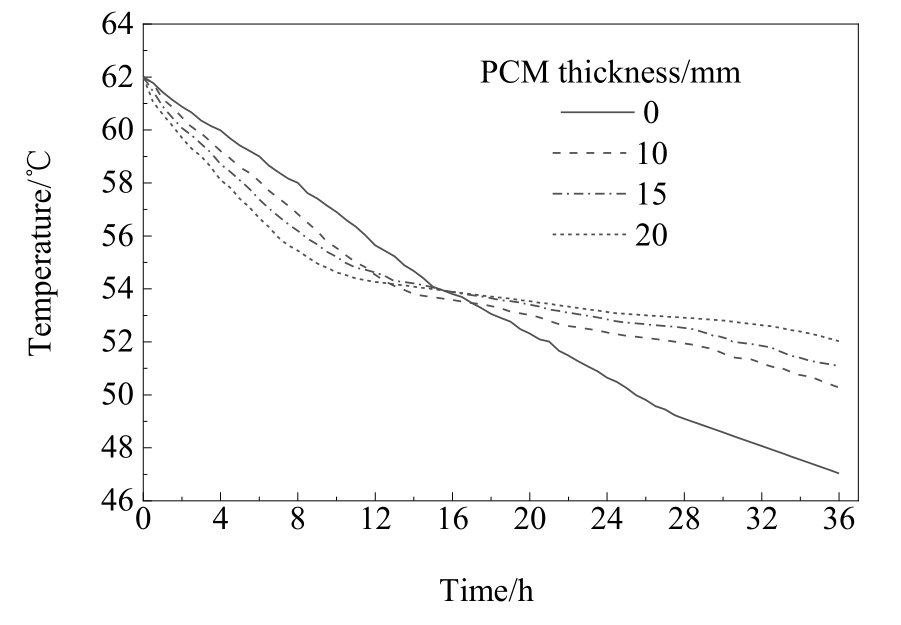

将相变储能技术应用于电热水器,并通过添加石墨纳米颗粒改善相变材料的导热特性,对其储能过程进行调节,可以起到“移峰填谷”的作用。建立了四种不同结构的电热水器三维模型,模拟了电热水器内部速度场与温度场分布特性。考察了进出口水管结构、电加热管布置方式、保温层结构等因素对热水器内部流场及传热特性的影响,研究了不同储能层厚度对电热水器储能的影响。结果表明,水平加热管与垂直加热管相比,加热过程中加热效率提高了2.2%;进水管管径增大1.5倍,热水输出率提升了17.9%;加入相变材料可在相同保温时间内(36 h)使水温最大提高10.6%。

中图分类号:

吴丽, 何杰, 鲁进利, 韩亚芳, 洪泽. 电热水器内部结构优化及储能特性研究[J]. 过程工程学报, 2021, 21(7): 786-793.

Li WU, Jie HE, Jinli LU, Yafang HAN, Ze HONG. Research on internal structure optimization and energy storage characteristics of electric water heater[J]. The Chinese Journal of Process Engineering, 2021, 21(7): 786-793.

| Case | Structure |

|---|---|

| 1 | Vertical heating tube+normal inlet pipe diameter |

| 2 | Horizontal heating tube+normal inlet pipe diameter |

| 3 | Vertical heating tube+1.5 times diameter of the inlet pipe |

| 4 | Horizontal heating tube+1.5 times diameter of the inlet pipe |

表1 不同结构电热水器

Table 1 Different structure electric water heaters

| Case | Structure |

|---|---|

| 1 | Vertical heating tube+normal inlet pipe diameter |

| 2 | Horizontal heating tube+normal inlet pipe diameter |

| 3 | Vertical heating tube+1.5 times diameter of the inlet pipe |

| 4 | Horizontal heating tube+1.5 times diameter of the inlet pipe |

| Material | Phase change temperature/℃ | Latent heat/(kJ/kg) | Specific heat/ [J/(kg·K)] | Heat conductivity coefficient/[W/(m·K)] | Density/(kg/m3) |

|---|---|---|---|---|---|

| Polyurethane | - | - | 1380 | 0.024 | 40 |

| Paraffine | 51~57 | 170 | 2100 | 0.25 | 760 |

| Paraffine+10wt% Graphite[ | 48~50 | 158.5 | 2235 | 0.94 | 877.5 |

表2 保温材料的物性参数

Table 2 Physical properties of thermal insulation materials

| Material | Phase change temperature/℃ | Latent heat/(kJ/kg) | Specific heat/ [J/(kg·K)] | Heat conductivity coefficient/[W/(m·K)] | Density/(kg/m3) |

|---|---|---|---|---|---|

| Polyurethane | - | - | 1380 | 0.024 | 40 |

| Paraffine | 51~57 | 170 | 2100 | 0.25 | 760 |

| Paraffine+10wt% Graphite[ | 48~50 | 158.5 | 2235 | 0.94 | 877.5 |

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Maximum temperature/℃ | 68.72 | 68.56 | 68.86 | 68.28 |

| Minimum temperature/℃ | 48.02 | 47.99 | 48.47 | 48.45 |

| Time/s | 370 | 390 | 430 | 460 |

| Water quality/kg | 30.25 | 31.89 | 35.16 | 37.62 |

| Water temperature/℃ | 63.53 | 63.49 | 63.82 | 63.50 |

| Shutdown temperature/℃ | 63.27 | 63.35 | 63.27 | 63.35 |

| Hot water output rate/% | 62.00 | 65.20 | 72.48 | 76.90 |

表3 不同方案热水输出率

Table 3 The hot water output rate under different schemes

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Maximum temperature/℃ | 68.72 | 68.56 | 68.86 | 68.28 |

| Minimum temperature/℃ | 48.02 | 47.99 | 48.47 | 48.45 |

| Time/s | 370 | 390 | 430 | 460 |

| Water quality/kg | 30.25 | 31.89 | 35.16 | 37.62 |

| Water temperature/℃ | 63.53 | 63.49 | 63.82 | 63.50 |

| Shutdown temperature/℃ | 63.27 | 63.35 | 63.27 | 63.35 |

| Hot water output rate/% | 62.00 | 65.20 | 72.48 | 76.90 |

图10 不同相变层厚度对保温过程中热水器平均水温的影响

Fig.10 The influence of different thicknesses of PCM on the average water temperature of electric water heater during heat preservation process

| 1 | 清华大学建筑节能研究中心. 中国建筑节能年度发展研究报告 [M]. 北京: 中国建筑工业出版社, 2018: 7-9. |

| Building Energy Conservation Research Center of Tsinghua University. 2018 Annual report on China building energy efficiency [M]. Beijing: China Aechitecture & Building Press, 2018: 7-9. | |

| 2 | 牛纪德, 周遵凯, 杨先亮, 等. 电热水器运行方式与能耗的理论分析 [J]. 山西建筑, 2012, 38(26): 213-214. |

| Niu J D, Zhou Z K, Yang X L, et al. Theoretical analysis of operation mode and energy consumption of electric water heaters [J]. Shanxi Architecture, 2012, 38(26): 213-214. | |

| 3 | 王烨, 宋荣飞, 胡悦, 等. 内置隔板开孔方式对太阳能蓄热水箱热分层的影响 [J]. 储能科学与技术, 2019, 8(5): 897-903. |

| Wang Y, Song R F, Hu Y, et al. Effect of obstacles with different opening means on thermal stratification in hot water storage tanks [J]. Energy Storage Science and Technology, 2019, 8(5): 897-903. | |

| 4 | Shao S, Shi W, Li X, et al. A new inverter heat pump operated all year round with domestic hot water [J]. Energy Conversion and Management, 2004, 45(13/14): 2255-2268. |

| 5 | Kim M, Kim M S, Chung J D. Transient thermal behavior of a water heater system driven by a heat pump [J]. International Journal of Refrigeration, 2004, 27(4): 415-421. |

| 6 | De Césaro Oliveski R, Krenzinger A, Vielmo H A. Comparison between models for the simulation of hot water storage tanks [J]. Solar Energy, 2003, 75(2): 121-134. |

| 7 | 李同, 陶汉中, 蒋川. 真空管型太阳热水器传热特性的数值分析 [J]. 太阳能学报, 2017, 38(5): 1247-1253. |

| Li T, Tao H Z, Jiang C. Numerical analysis on heat transfer characteristic of evacuated tube solar water heater [J]. Acta Energiae Solaris Sinica, 2017, 38(5): 1247-1253. | |

| 8 | 王登甲, 刘艳峰. 太阳能热水采暖蓄热水箱温度分层分析 [J]. 建筑热能通风空调, 2010, 29(1): 16-19. |

| Wang D J, Liu Y F. Temperature stratification analysis of solar hot water heating storage tank [J]. Building Energy & Environment, 2010, 29(1): 16-19. | |

| 9 | 黄建春, 李光正, 江立新, 等. 封闭腔内层流自然对流换热过渡层数值研究 [J]. 华中科技大学学报, 2001, (5): 51-53. |

| Huang J C, Li G Z, Jiang L X, et al. Numerical study on the flow transition in laminar natural convection flow in a square cavity [J].Journal of Huazhong University of Science and Technology, 2001, (5): 51-53. | |

| 10 | 鲁进利, 吕勇军, 韩亚芳, 等. 细小槽道换热器内相变微胶囊悬浮液对流传热DPM模拟 [J]. 过程工程学报, 2018, 18(5): 951-956. |

| Lu J L, Lü Y J, Han Y F, et al. Simulation on convective heat transfer of MPCMS in minichannel heat exchanger based on DPM model [J]. The Chinese Journal of Process Engineering, 2018, 18(5): 951-956. | |

| 11 | Ma X C, Liu Y J, Liu H, et al. Fabrication of novel slurry containing graphene oxide-modified microencapsulated phase change material for direct absorption solar collector [J]. Solar Energy Materials and Solar Cells, 2018, 188: 73-80. |

| 12 | 张宇, 田丽亭, 岳小棚, 等. 槽式太阳能集热管内相变微胶囊悬浮液的热力性能分析 [J]. 过程工程学报, 2020, 20(3): 276-284. |

| Zhang Y, Tian L T, Yue X P, et al. Thermal mechanical characteristics analysis of trough solar collector with microencapsulated phase change suspensions [J]. The Chinese Journal of Process Engineering, 2020, 20(3): 276-284. | |

| 13 | 鲁进利, 张汪林, 韩亚芳, 等. 细小圆管内Micro-PCMS紊流对流传热特性的CFD-DPM模拟 [J]. 过程工程学报, 2015, 15(5): 758-763. |

| Lu J L, Zhang W L, Han Y F, et al. CDF-DPM simulation on characteristics of turbulent flow and heat transfer for micro-PCMS in mini-pipe [J]. The Chinese Journal of Process Engineering, 2015, 15(5): 758-763. | |

| 14 | 邹得球, 詹建, 李乐园, 等. 热水器用相变储热材料的研究进展 [J]. 化工进展, 2017, 36(1): 268-273. |

| Zhou D Q, Zhan J, Li L Y, et al. Research progress of phase change thermal energy storage materials in water heater [J]. Chemical Industry and Engineering Progress, 2017, 36(1): 268-273. | |

| 15 | Alexios P, Sarvenaz S, Vladimir P, et al. Evacuated tube solar collectors integrated with phase change materials [J]. Solar Energy, 2016, 129: 10-19. |

| 16 | Miqdam T C, Kazem H A. Water solar distiller productivity enhancement using concentrating solar water heater and phase change material (PCM) [J]. Case Studies in Thermal Engineering, 2015, 5: 151-159. |

| 17 | Wang W, He S, Guo S, et al. A combined experimental and simulation study on charging process of erythritol-HTO direct-blending based energy storage system [J]. Energy Conversion and Management, 2014, 83: 306-313. |

| 18 | Summers E K, Antar M A, John H L V, et al. Design and optimization of an air heating solar collector with integrated phase change material energy storage for use in humidification-dehumidification desalination [J]. Solar Energy, 2012, 86: 3417-3429. |

| 19 | 巫江虹, 杨兆光, 吴青昊, 等. 热泵热水器用相变蓄热材料的性能研究 [J]. 太阳能学报, 2011, 32(5): 674-678. |

| Wu J H, Yang Z G, Wu Q H, et al. Experimental study on phase-change performance of thermal storage materials in heat pump water heater [J]. Acta Energiae Solaris Sinica, 2011, 32(5): 674-678. | |

| 20 | 周楚, 陈华, 史德福, 等. 相变蓄热式热泵热水器性能实验研究 [J]. 建筑科学, 2014, 30(4): 5-9. |

| Zhou C, Chen H, Shi D F, et al. Experimental study on performance of phase-transition thermal-storage heat pump water heater [J]. Building Science, 2014, 30(4): 5-9. | |

| 21 | 吴淑英. 纳米复合蓄热材料强化相变传热实验与数值模拟研究 [D]. 广州: 华南理工大学, 2010: 79-95. |

| Wu S Y. Enhanced heat transfer experimental and simulation research of nanocomposite phase change materials [D]. Guangzhou: South China University of Technology, 2010: 79-95. | |

| 22 | 冉茂宇. 非出水时段电热水器加热时间与能耗的预测模型 [J]. 华侨大学学报(自然科学版), 2016, 37(2): 247-251. |

| Ran M Y. Preditction model of the heating time and energy consumption of electric water heater during the un-draining period [J]. Journal of Huaqiao University (Natural Science), 2016, 37(2): 247-251. |

| [1] | 姜保成 肖涛 王松松 郭学益 王亲猛. 氧枪区位置对大型铜熔炼氧气底吹炉流动特性影响研究[J]. 过程工程学报, 2025, 25(2): 150-158. |

| [2] | 张建文 苏国庆 冯磊磊 李彦 张帆 卢世林 赵亚辉 盛刚. 加氢装置高压换热器铵盐结晶行为研究[J]. 过程工程学报, 2025, 25(1): 20-33. |

| [3] | 张鑫镝 赵杰 郭建华 张卫义. 下弯管直弯比对新型密排式液-固循环流化床换热器稳定流态化性能的影响[J]. 过程工程学报, 2024, 24(9): 1016-1026. |

| [4] | 张蕊 于庆波 娄一荻. 烟气再循环率对水泥回转窑加热过程的影响[J]. 过程工程学报, 2024, 24(9): 1027-1035. |

| [5] | 屠楠 王驰宇 刘晓群 刘家琛 方嘉宾. 多级挡板对横流鼓泡床颗粒停留时间分布影响的数值模拟[J]. 过程工程学报, 2024, 24(9): 1047-1057. |

| [6] | 陈简一 许闽 仝仓 黄彩凤 淮秀兰. 基于CFD-DEM的新型挡板式移动床反应器内Ca(OH)2/CaO热化学储能过程模拟[J]. 过程工程学报, 2024, 24(8): 894-903. |

| [7] | 尹孝辉 刘辉 嵇翔宇 独家卿 王瑞 胡磊. 马氏体相变对CMT熔覆9Cr-1Mo涂层残余应力影响的数值模拟[J]. 过程工程学报, 2024, 24(8): 926-936. |

| [8] | 张明 孙欢 王强强 陈家庆 尚超 李想 王春升 孔令真. 管式旋流气液分离器流场特性与分离性能研究[J]. 过程工程学报, 2024, 24(7): 772-782. |

| [9] | 邢谷雨 袁俊飞 王林 江河 冯梓城 王梦轩. 矩形周期性扩缩微通道内沸腾流动与传热[J]. 过程工程学报, 2024, 24(7): 793-804. |

| [10] | 陆彪 王行银 胡青云 陈燕 陈德敏 高靖. 富氧燃烧条件对加热炉板坯加热过程的影响[J]. 过程工程学报, 2024, 24(7): 805-814. |

| [11] | 孙祎 钱付平 于灵涛 吴越 黄乃金 吴昊. 回转式换热器换热元件换热及阻力特性的数值研究[J]. 过程工程学报, 2024, 24(6): 670-680. |

| [12] | 莫畏难 苏有勇 朱冬冬. 低管径比固定床反应器床层特性及流动传热模拟[J]. 过程工程学报, 2024, 24(6): 692-704. |

| [13] | 张馨艺 徐宁文 李小明 王树众. 辅助气淬风优化熔渣离心粒化特性数值模拟[J]. 过程工程学报, 2024, 24(5): 523-532. |

| [14] | 赵阳 谢明辉 向家伟 刘肖肖 李帅亮 吕世军 吴亮 周国忠 张庆华 杨超. 不同桨型组合淤浆聚合釜内固液悬浮特性研究[J]. 过程工程学报, 2024, 24(4): 403-413. |

| [15] | 金明芳 何峰 谢峻林 梅书霞 李全亮. 700 t/d浮法玻璃熔窑中玻璃液流动特性与澄清过程研究[J]. 过程工程学报, 2024, 24(4): 425-434. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||